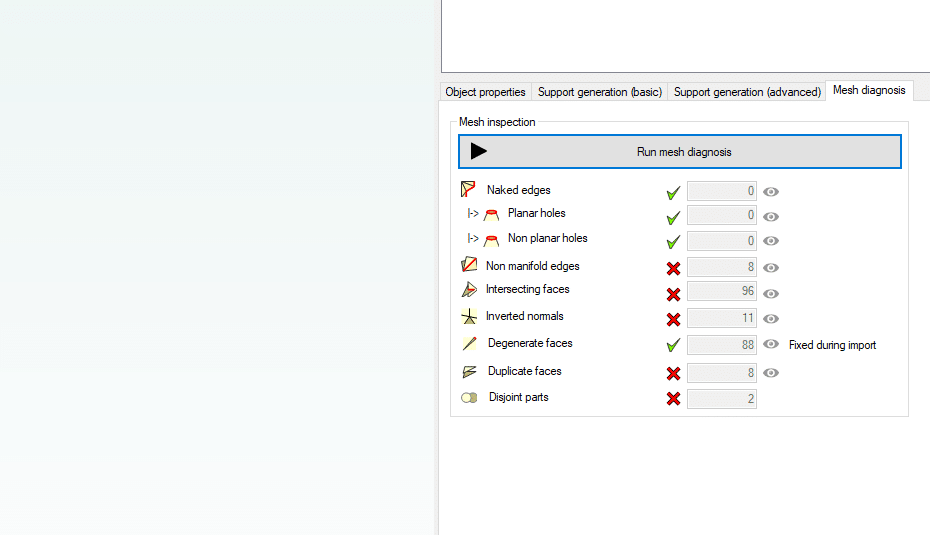

Mesh errors and diagnosis

When a part is imported and read a subset of possible errors is checked. (Naked edges, Non manifold edges, degenerate faces and duplicate faces) If errors are detected that might cause the print to fail the software will add a yellow exclamation mark to your part. When in support mode, a full mesh diagnosis can be run on the part. You find the mesh diagnosis in the tab next to the supporting tabs. By clicking the eye icon behind each error you can view error in your part. We describe all possible mesh errors shortly below.

NAKED EDGES AND HOLES

Naked edges are edges that only have 1 connected triangle face. This means there is a hole in the mesh. This might result in artifacts during slicing.

Planar holes are flat holes that reside in 1 plane. All naked edges on the border are connected. They are easily fixed by triangulation of the hole.

Non planar holes have edges that lie in different planes. Hence they are harder to repair automatically.

NON MANIFOLD EDGES

Non manifold edges are edges that have 3 or more faces adjacent to it. They might result in slicing errors but not necessarily.

INTERSECTING FACES

Intersecting faces means the faces intersect. This is not necessarily a bad thing. It can mean you have multiple disjoint parts or self intersecting parts.

INVERTED NORMALS

Faces with inverted normals pose a problem during slicing. The slice engine won’t know if a face is representing the inside or outside of the model.

DEGENERATE FACES

Degenerate faces have 2 or 3 vertices that are equal. They are not visible.

DUPLICATE FACES

Duplicate faces share exactly the same vertices. They may cause problems during slicing routines.

DISJOINT PARTS

Disjoint parts can existing in a single mesh. This is not necessarily a problem. However it may become a problem with further operations like hollowing when multiple self intersections can occur.